Achieving Lightweight Plastic Parts with Required Structure Strength

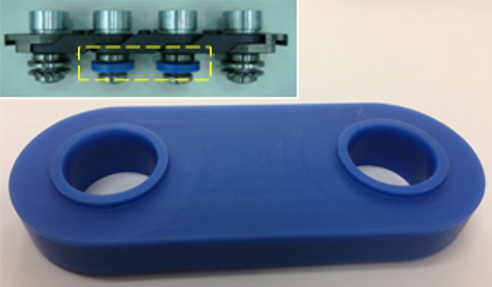

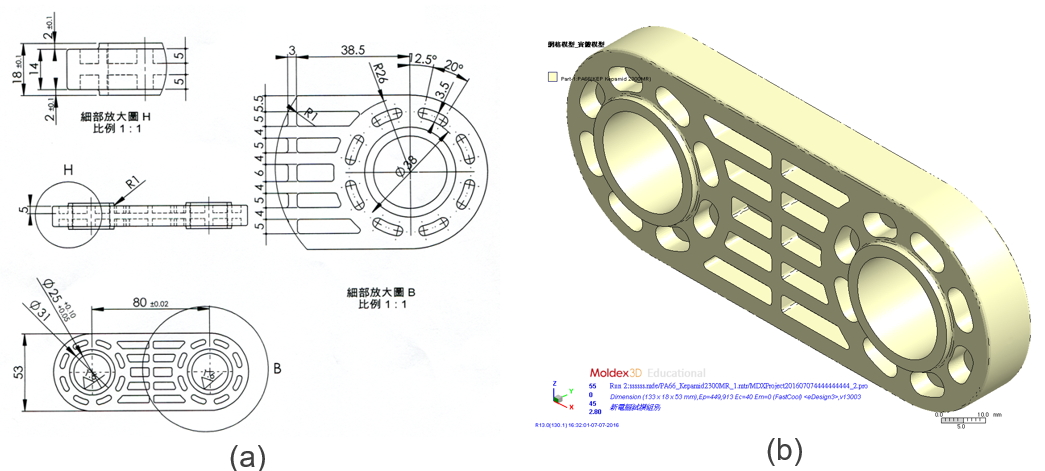

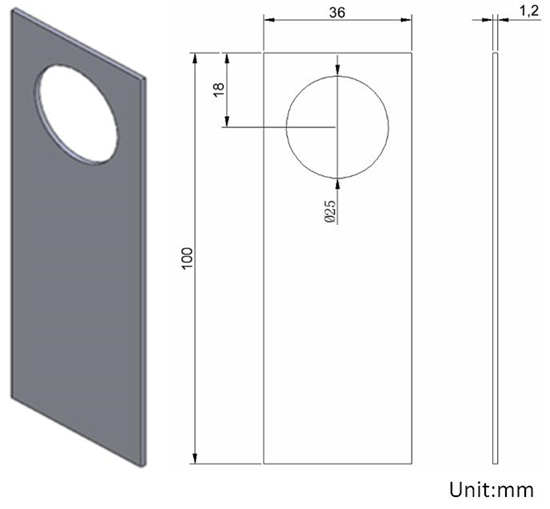

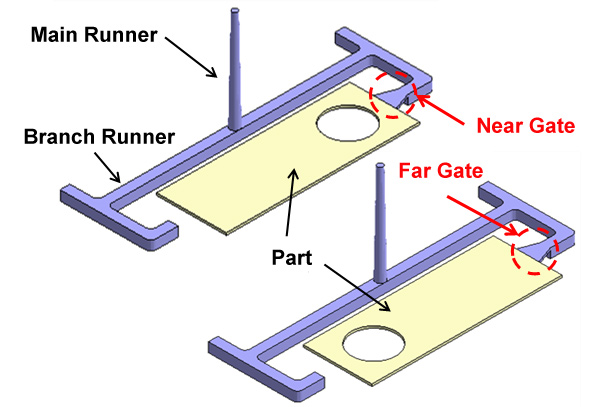

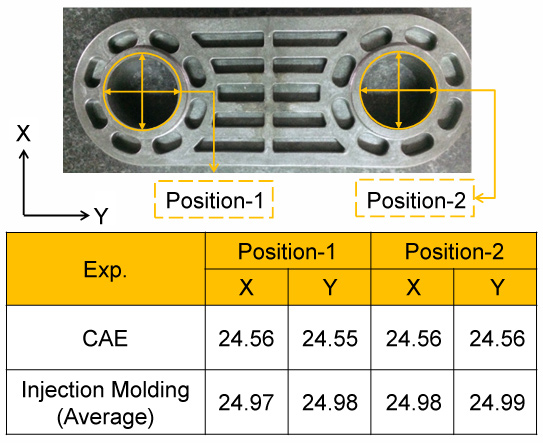

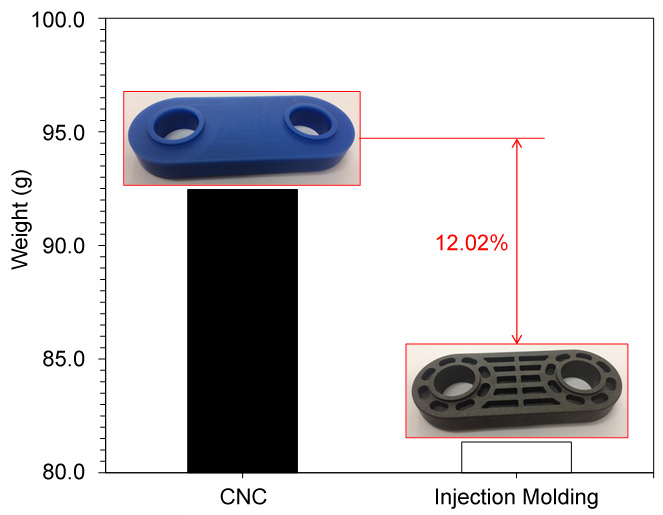

For over 50 years, Feng Chia University (FCU) has steadily increased in size and scope. Over 20,000 students are currently enrolled in undergraduate, master’s, and doctoral degree programs for working professionals (Source). In recent years, the manufacturing industry has been reducing material consumption, energy use, and shortening production cycles due to the growing environmental consciousness. However, many structural plastic parts are CNC-machined, which requires longer production cycles and higher costs, resulting in material waste. In this project, Feng Chia University students aimed to explore the possibility of replacing CNC machining with injection molding to create slider blocks with glass-filled nylons (PA66+GF30%) to deliver lightweight, functional, and durable parts. Feng Chia University students used Moldex3D simulation software to predict the effects of reinforced fibers and modified material properties on part shrinkage. In addition, they also used Moldex3D to examine the shrinkage of the holes and validated the results with experimental data. The experimental data had good agreement with the simulation results. With the help of simulation and experimental validation, the part shrinkage was successfully reduced and met the needs for stiffness and light-weighting. In a blow molding machine, the slider blocks are important parts that connect the slide bearings and the conveying preform (Fig. 1). To reduce the manufacturing cost and achieve the purpose of lightweight, in this study, the Feng Chia University team planned to replace the CNC machining with plastic injection molding, and predict the flow behavior, fiber orientation, shrinkage, etc. for the new product design through Moldex3D. The new product design concept is shown in Fig. 2. To understand the problems that may occur during product molding, the team compared the test model’s experiment with Moldex3D’s analysis, and then applied the research results to actual product development and manufacturing. Fig. 3 shows the dimensions of the test model. The roundness of the hole on the part was critical since it was supposed to connect the slide bearings. The gate design included the gates close to and far from the hole (Fig. 4). How the gate positions would affect the hole roundness and shrinkage changes were then observed. To confirm whether the structural strength of the product meets the target, the team used Moldex3D to predict the volume shrinkage and roundness of the product after adding the fiber. And finally, the experimental data had good agreement with the simulation results (as shown in Fig. 5). Through the help of Moldex3D, the Feng Chia University team successfully reduced product weight by more than 12% to achieve a lightweight design (as shown in Fig. 6). They also found the reinforcement of glass fiber could make the product structure reach the target strength. The product shrinkage was improved by more than 22%, ensuring the roundness. Metal High Speed Stamping,High Speed Stamping,High Speed Metal Stamping,High Speed Punch Press ShenZhen Jakeconn Precision Technology Co., Ltd. , https://www.jkpmoulds.comEdited by Pierre Yeh, Engineer at Technical Support Team, Moldex3D

Executive Summary

Challenges

Solutions

Benefits

Case Study

Fig. 1 The slider blocks

Fig. 2 Revised innovative product design (a: 2D Design; b: 3D Design)

Fig. 3 The test mold with round hole design

Fig. 4 Different gate locations

Fig. 5 Shrinkage comparison of Moldex3D and experiment

Results

Fig. 6 Product weight comparison