Model NO.: KS-420

Trademark: KS

Transport Package: Wooden Case

Specification: stainless steel

Origin: Shandong, China

Model NO.: KS-420

Trademark: KS

Transport Package: Wooden Case

Specification: stainless steel

Origin: Shandong, China

Detailed Product Description

| Material: |

Equipments Are Made Of Stainless Steel |

Design: |

Equipment Can Be Designed For Customers |

| Automatic: |

Full Automatic |

Roll Film Dimension:: |

≤720mm |

| Heads: |

Ten Heads Weighter |

Weight: |

1500kg |

Â

High Automation Food Packaging Machinery For Granule / Puffing Food

Â

Specifications

It is suitable for weighing of granule, slice, roll or irregular shape materials such as cereal, pasta, candy, seed, chips

1. Application:

It is suitable for weighing of granule, slice, roll or irregular shape materials such as cereal, pasta, candy, seed, chips, coffee bean, nut, puffy food, biscuit, chocolate, pet food, frozen foods, etc. It is also suitable for non-food industry such as screws, bolts and plastic components.

Â

2. Main Features:

* Amplitude can be adjusted freely and individually in running status, More friendly HMI. Â

* Multi-language operating interface.

* Mouse, USB and SD card compatible with touch screen.

* Stagger dump prevents products blockageÂ

Â

3. Special Features:

* Modular electronic system makes maintenance easier and at lowest cost

* AD card are inter-changeable ,easy to be replaced ;

* Different authority managements, more user- friendly

* HMI can be upgraded by U disk

4. Technical Parameters

| Model |

KS-380 |

KS-520 |

| Packing speed |

30-60 (bags/min)Â |

20-50 (bags/min)Â |

| Packing product size  |

(L)80-350mm (W)150-270mm |

(L)80-450mm (W)150-350mm |

| Roll Film Width: |

≤580mm |

≤720mm |

| roll film dimension |

Φ450mm |

| Air Consumption |

2.0m3/min 4.5kg/cm2 |

3.0m3/min 6kg/cm2 |

| Sealing type |

Back side sealing |

| Voltage: |

220V 50/60Hz |

| Total power |

1.8kw |

2.2kw |

| Gross weight    |

1400kg |

1500kg |

| Outside dimensions |

5258*3610*3650mm |

5258*3610*3650mm |

| Â |

|

|

|

Optinal spare partsÂ

1. Air compressor

2. Finished product conveyor

3. Checkweigher

4. Metal detector

5. Nitrogen-making machine

Optional function devicesÂ

1. Hole punch device

2. Tear notch device

3. Bag-linking control device

4. Air exhaust device

5. Nitrogen inflation device

6. Liquid pump device for packing liquid material

Kindly reminder

Please tell us the following information when you send us an inquiry.Base on your message,we will suggest the  optimum machine or options to you for  reference.Thank you.

1. Bag dimension

2. Bag weight

3. Filling material

4. Bag shape

5. Bag material

Â

Our servicesÂ

Installation:

1. We provide videos and instruction manual to show the process of installation.

2. We provide training for installation for free in our factory.

3. We can send technician to buyer's factory to install the machine and provide training service.

Â

After Sales Service:

1. One year quality warranty and free lifetime technique support.

2. Free spare parts would be supplied if machine broken within warranty period except the easily damaged parts.

3. After the warranty period, the spare parts for replacement are offered based on certain charge.

Unloading finished products conveyor

Detailed Product Description

| Material: |

Equipments Are Made Of Stainless Steel |

Design: |

Equipment Can Be Designed For Customers |

| Automatic: |

Full Automatic |

Roll Film Dimension:: |

≤720mm |

| Heads: |

Ten Heads Weighter |

Weight: |

1500kg |

Â

High Automation Food Packaging Machinery For Granule / Puffing Food

Â

Specifications

It is suitable for weighing of granule, slice, roll or irregular shape materials such as cereal, pasta, candy, seed, chips

1. Application:

It is suitable for weighing of granule, slice, roll or irregular shape materials such as cereal, pasta, candy, seed, chips, coffee bean, nut, puffy food, biscuit, chocolate, pet food, frozen foods, etc. It is also suitable for non-food industry such as screws, bolts and plastic components.

Â

2. Main Features:

* Amplitude can be adjusted freely and individually in running status, more friendly HMI. Â

* Multi-language operating interface.

* Mouse, USB and SD card compatible with touch screen.

* Stagger dump prevents products blockageÂ

Â

3. Special Features:

* Modular electronic system makes maintenance easier and at lowest cost

* AD card are inter-changeable ,easy to be replaced ;

* Different authority managements, more user- friendly

* HMI can be upgraded by U disk

4. Technical Parameters

| Model |

KS-380 |

KS-520 |

| Packing speed |

30-60 (bags/min)Â |

20-50 (bags/min)Â |

| Packing product size  |

(L)80-350mm (W)150-270mm |

(L)80-450mm (W)150-350mm |

| Roll Film Width: |

≤580mm |

≤720mm |

| roll film dimension |

Φ450mm |

| Air Consumption |

2.0m3/min 4.5kg/cm2 |

3.0m3/min 6kg/cm2 |

| Sealing type |

Back side sealing |

| Voltage: |

220V 50/60Hz |

| Total power |

1.8kw |

2.2kw |

| Gross weight    |

1400kg |

1500kg |

| Outside dimensions |

5258*3610*3650mm |

5258*3610*3650mm |

| Â |

|

|

|

Optinal spare partsÂ

1. Air compressor

2. Finished product conveyor

3. Checkweigher

4. Metal detector

5. Nitrogen-making machine

Optional function devicesÂ

1. Hole punch device

2. Tear notch device

3. Bag-linking control device

4. Air exhaust device

5. Nitrogen inflation device

6. Liquid pump device for packing liquid material

Kindly reminder

Please tell us the following information when you send us an inquiry.Base on your message,we will suggest the  optimum machine or options to you for  reference.Thank you.

1. Bag dimension

2. Bag weight

3. Filling material

4. Bag shape

5. Bag material

Â

Our servicesÂ

Installation:

1. We provide videos and instruction manual to show the process of installation.

2. We provide training for installation for free in our factory.

3. We can send technician to buyer's factory to install the machine and provide training service.

Â

After Sales Service:

1. One year quality warranty and free lifetime technique support.

2. Free spare parts would be supplied if machine broken within warranty period except the easily damaged parts.

3. After the warranty period, the spare parts for replacement are offered based on certain charge.

Unloading finished products conveyor

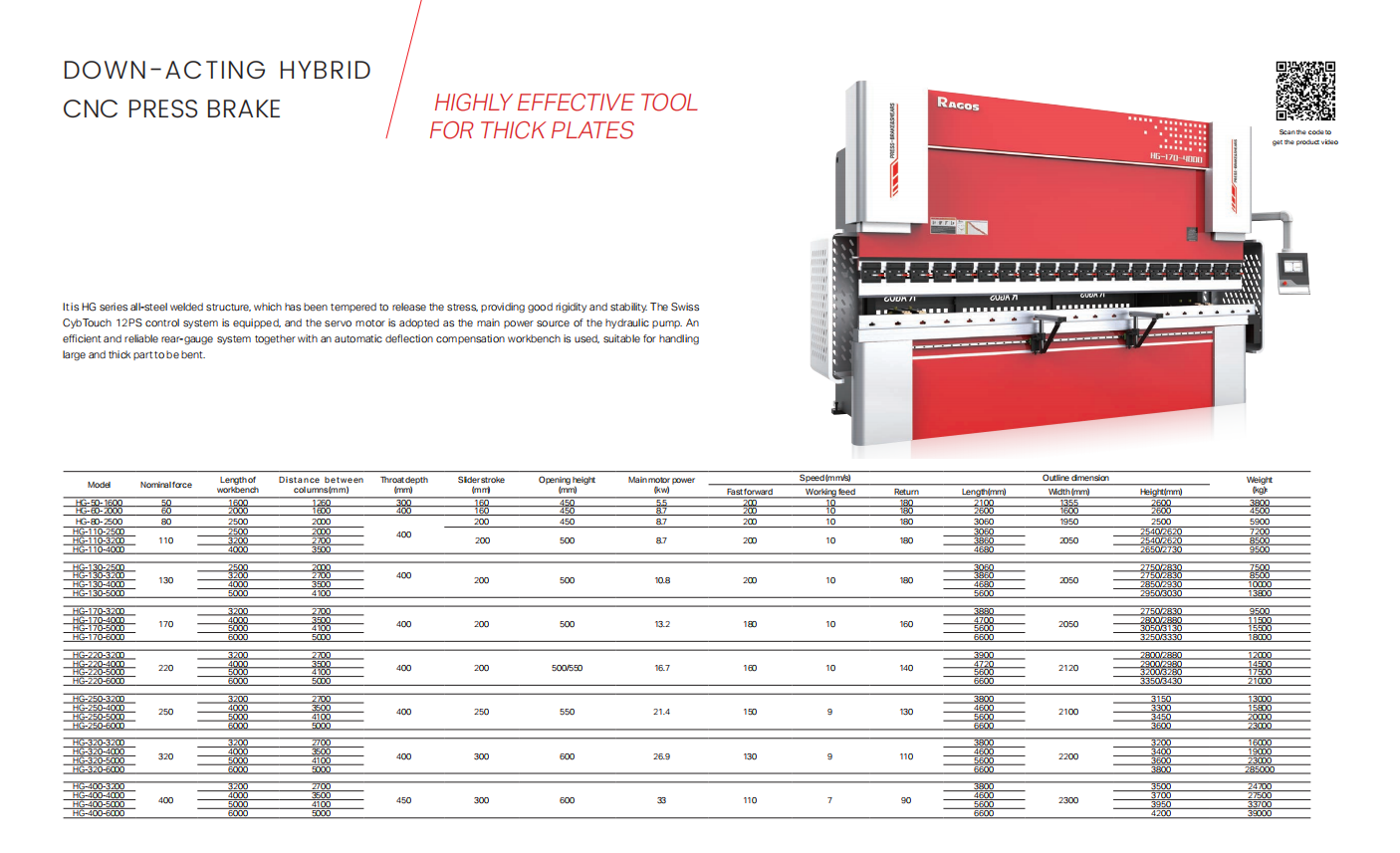

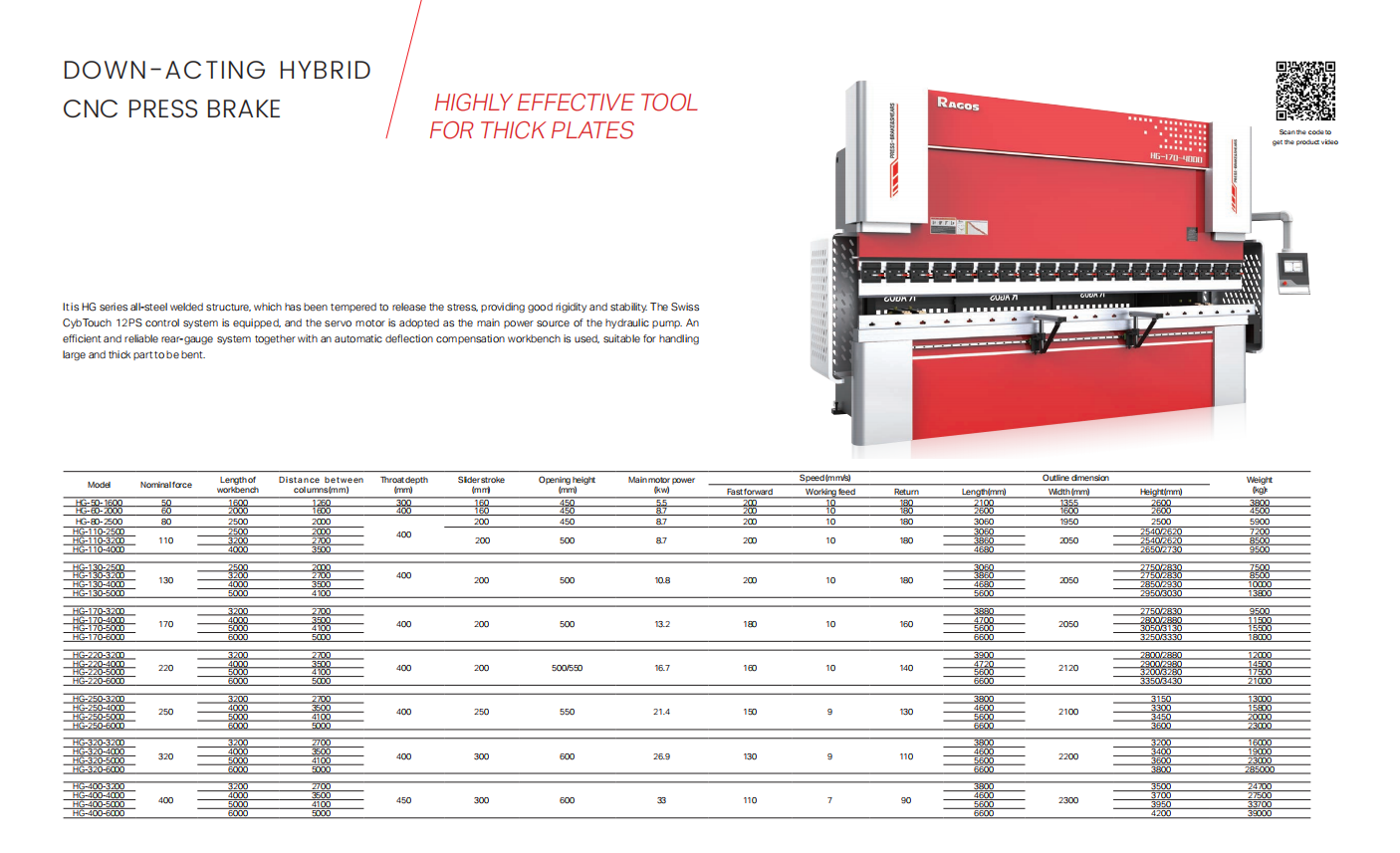

Down-acting Press Brake

Dual servo hybrid CNC Press Brake

Features:

Introduction:

Features And Function

Fast - 10% performance increase by reducing cycle time

High efficiency - 50% increase in energy efficiency (compared to traditional systems)

Precise - positioning accuracy reaches 0.005mm

Features And Function

Fast - 10% performance increase by reducing cycle time

High efficiency - 50% increase in energy efficiency (compared to traditional systems)

Precise - positioning accuracy reaches 0.005mm

Reliable - minimal risk of leakage

Low Noise - Noise reduction in all operating modes

compact - creating new spaces on the midplane

Compatible - easy integration into CNC

Optimization - less installation and service fees

Environmental protection - the amount of hydraulic oil is greatly reduced

Down-acting press brake,sheet metal panel benders,cnc panel bender,Automatic Panel Bender,Sheet Metal Bending Center,ragos

FOSHAN RAGOS NC EQUIPMENT CO.,LTD. , https://www.ragosnc.com